Be Proactive Rather Than Reactive

Adaptive Experimental Design

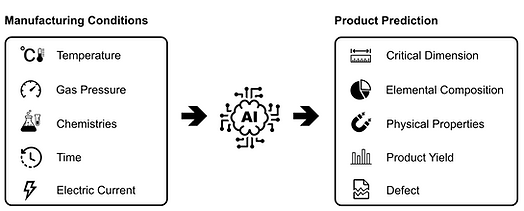

InsightLab™ performs robust data-driven AI/ML predictive modeling to facilitate the Design of Experiment (DoE), enabling scientists and engineers to simulate experiments and predict outcomes before physically conducting them, thus saving time and resources by reducing the number of unnecessary experimentations.

Process Control & Optimization

The InsightLab™ platform employs robust AI/ML algorithms to optimize advanced manufacturing process, all the while reducing the high cost of rework and recalls. In real time, it can:

-

Monitor process parameters while detecting process anomalies

-

Track dynamic process metrics, reducing tremendous manual effort

-

Provide prescriptive recommendations, enabling early intervention and prevent process deviations or serious defects

Property & Performance Prediction

InsightLab™ uses AI and ML predictive modeling for virtual metrology (VM), which means we can estimate a product's property or quality directly from data without physical measurements.

This brings several benefits:

-

Monitoring product quality in real time

-

Preserving process efficiency and consistency

-

Reducing the intensive needs of high-cost physical measurements

-

Significantly increasing the confidence in process and yield control

-

Largely accelerating the cycle time of product R&D

Predictive Maintenance (PdM)

The InsightLab™ AI PdM module continuously monitors your machinery and equipment assets before major problems emerge. Using dynamic analytical and performance metrics, it can predict when your equipment needs services or replacements.

-

Enables timely and proactive maintenance

-

Prevents unexpected equipment failures and costly downtime

-

Extends equipment and assets lifespan

-

Enhances overall operational efficiency